Concreat and Sustainability: Building a Greener Philippines

Concreat and Sustainability: Building a Greener Philippines, One Project at a Time

Every cement bag carries the foundation of progress – the roads that connect us, the homes that shelter us, and the cities that continue to rise. But for Concreat Holdings Philippines (CHP), true progress means building a future that is both strong and sustainable.

As a proudly Filipino company under the DMCI Group, Concreat is taking bold steps to protect the environment and support local communities through cleaner, greener practices – from waste management partnerships to coastal clean-ups and co-processing innovations.

A green challenger for a changing world

Concreat continues to manufacture high-quality cement brands – APO, Island, and Rizal cement – while championing responsible business practices that promote proper environmental stewardship, such as waste management and circular economy practices.

Every project and partnership reflects one goal: to build a healthier, safer, and more resilient Philippines. Whether it’s working with local governments on waste diversion or protecting marine habitats, Concreat is redefining what it means to be a cement company in the modern age, one that’s as committed to people and the planet as it is to progress.

Tackling the country’s waste challenge

Did you know? The Philippines generates 14.6 million tons of municipal solid waste each year, enough to fill a small island. A large portion of this waste ends up in dumpsites, where it poses serious health and environmental risks to nearby communities.

Left unmanaged, these wastes release toxic fumes and gases that contribute to global warming. They contaminate water sources, clog waterways, and increase the frequency of flooding. For Concreat, addressing this challenge is part of our responsibility as a company that builds for the long term.

That’s why Concreat is partnering with local governments and private organizations to find sustainable, scalable ways to manage waste and turn what was once a problem into part of the solution.

Partnering for cleaner cities: Responsible waste management with CDO Foodsphere and Binangonan LGU

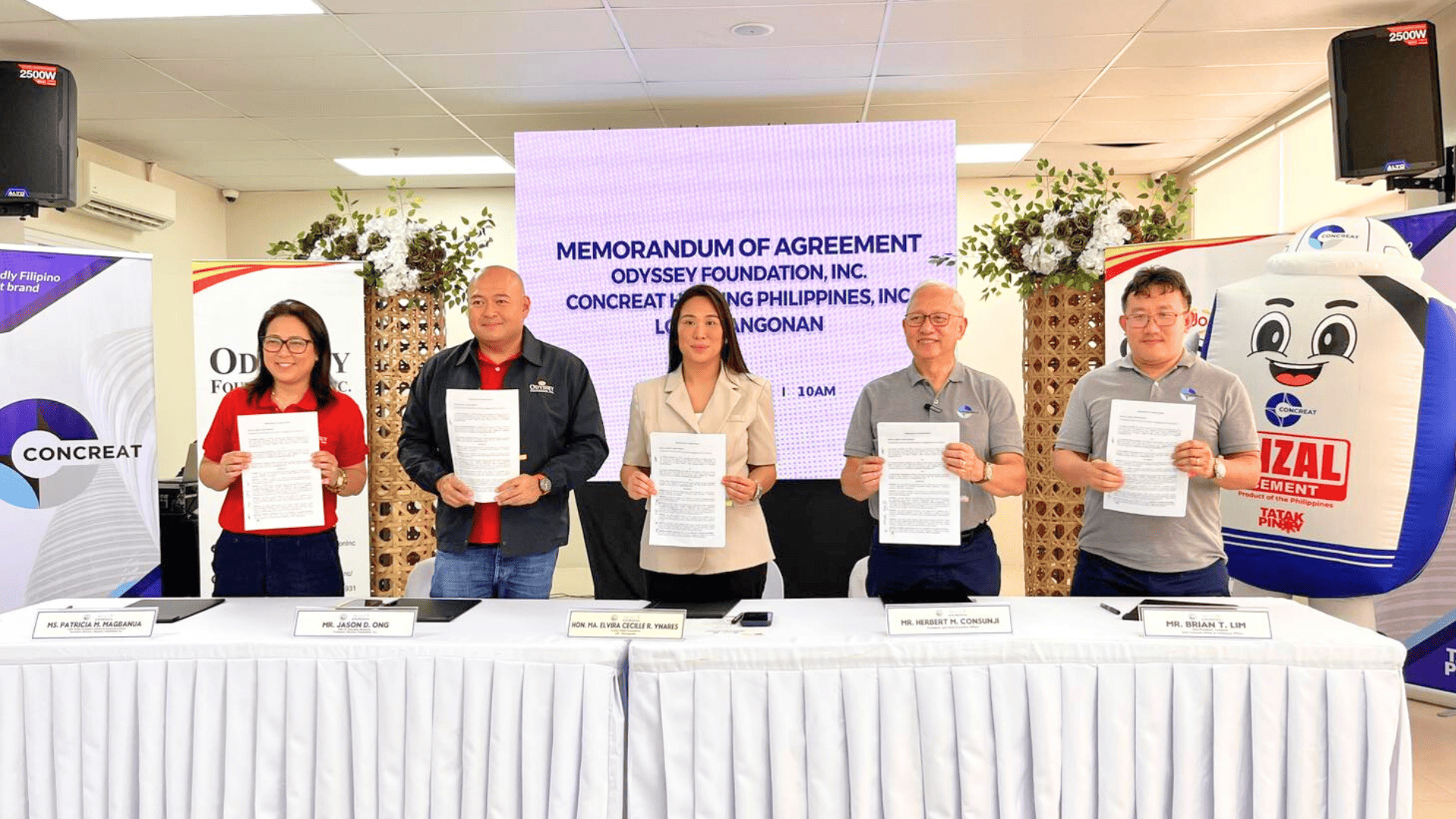

Concreat strengthened its partnerships with CDO Foodsphere and the local government unit (LGUs) of Binangonan, Rizal, to promote responsible waste management. These partnerships aim to reduce reliance on landfills and encourage people to segregate and properly dispose of their waste.

Through these collaborations, Concreat helps local authorities collect and transport residual and non-recyclable waste from communities to its cement plants for co-processing, an eco-friendly alternative to conventional waste disposal. The initiative helps clean up cities, supports local employment, and raises awareness of sustainable waste practices among communities.

Co-processing: Turning waste into worth

At the heart of Concreat’s sustainability strategy is co-processing, a proven waste-management technology that converts waste into alternative fuels and raw materials for cement production.

Instead of letting plastic, rubber, and other residual waste sit in landfills, co-processing integrates them into the cement manufacturing process. Inside Concreat’s high-efficiency kilns – operating at temperatures around 1,500°C – waste materials are safely broken down leaving no harmful residues behind.

The result? A dual benefit for the environment: reduced landfill volume and methane emissions, as well as lower fossil fuel consumption and carbon footprint in cement production.

Concreat’s co-processing facilities follow a five-step process to ensure safe, compliant, and sustainable waste handling:

-

Evaluation: Qualified waste streams undergo chemical analysis to determine suitability.

-

Transportation: Waste is transported directly from the partner’s site to Concreat’s plant by trained drivers.

-

Pre-treatment: Materials are shredded, blended, and refined to prepare them for co-processing.

-

Co-processing: Waste is safely processed in controlled conditions inside cement kilns.

-

Certification: Partners receive documentation validating the proper disposal of their waste in an ISO-certified facility.

By providing end-to-end traceability and assurance, Concreat ensures that every kilogram of waste is managed responsibly and contributes to the Philippines’ journey toward zero waste.

Beyond cement: A culture of environmental stewardship

At Concreat, sustainability is a mindset that extends beyond our production lines and shapes how we engage with communities and the environment.

Across our sites, employees regularly participate in coastal clean-up drives, removing plastic waste and debris that pollute marine ecosystems. These efforts are tangible expressions of Concreat’s mission to restore and protect the natural environments that sustain Filipino communities.

In collaboration with partner organizations, Concreat also conducts educational programs to promote proper waste segregation and recycling among residents, students, and local businesses. Sustainability starts with awareness, and every small action can ripple into lasting impact.

Empowering communities through circular solutions

Concreat’s partnerships and programs also create shared value for communities. Waste collection and segregation initiatives provide livelihood opportunities for local workers, while cleaner surroundings improve public health and safety.

By integrating sustainability into our operations and outreach, Concreat demonstrates that business success and environmental stewardship can go hand in hand.

Building a better future, one project at a time

As infrastructure needs grow nationwide, Concreat remains focused on delivering reliable products and solutions that support long-term progress. Co-processing and strategic partnerships are helping optimize resources, improve efficiency, and enhance operations across its facilities.

Beyond producing cement, Concreat is committed to building a stronger and more resilient Philippines – one where industries, communities, and local economies grow together.